Bristol, 15th February 2018 – The Centre for Modelling and Simulation (CFMS) and the National Composites Centre (NCC) are working to demonstrate the integration of predictive machine learning to drive improvements and minimise variability within a composites manufacturing process.

The collaborative project, Computer Learning in Automated Manufacturing Processes (CLAMPS), will result in a physical demonstrator at the NCC, which will automatically adjust the manufacturing process parameters to ensure consistently high-quality parts. The project will highlight the digitalisation and automation steps necessary for incorporation into a liquid composite moulding process to reduce the need for rework, scrap, or repair, ultimately saving costs.

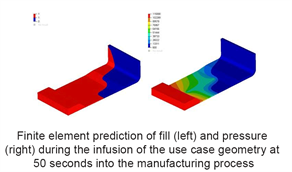

The ability to detect and control defect formation will be based on the output of over 15,000 virtual manufacturing simulations of a liquid composite resin infusion process. A machine learning algorithm will be used to process the data and classify the decisions made during the infusion process to minimise the formation of porosity and dry-spot defects. In the physical manufacturing process, the flow of resin is monitored using intelligently positioned sensors, enabling a real-time understanding of the flow inside a closed mould. The machine learning model developed from the virtual manufacturing simulations will be used to predict and mitigate the formation of defects by selectively opening and closing inlet and outlet valves to influence the flow of resin.

The pilot project will act as a proof-of-principle for the application of machine learning to control a composites manufacturing process. It has the potential to be upscaled to complex composite part geometries for industries including aerospace, automotive and renewables.

Sam Paice, CFMS Chief Operating Officer, commented “Through the creation of a series of collaborative proof of concept digital twin demonstrators, we want to highlight the potential for improvements and accelerated development cycles in the design and manufacturing process.”

Giuseppe Dell’Anno, Chief Engineer at the NCC, explains that “many composites manufacturing processes require the intervention of experienced engineers to overcome process and material variability. In this demonstration, the in-process decision making is being automated, using digital process modelling and advanced machine learning techniques. The NCC and CFMS are helping to bring the composites industry one step closer to intelligently automated production.”

The project will last approximately six months, and builds on the relationship between the two centres of excellence. Organisations interested in learning about the demonstrator, and applying the techniques to their own products and facilities are invited to contact the NCC and CFMS.

For all CFMS interviews and press enquiries, please contact our team.

For all NCC interviews or media enquiries, contact: Mary Page t: 07530366482 e: mary.page@nccuk.com

About CFMS

The Centre for Modelling and Simulation (CFMS) is proud to be a growing, independent and not-for-profit organisation that specialises in digitally enabled high value design capability. We promote advanced modelling and simulation, underpinned by High Performance Computing (HPC), pushing the boundaries of technology.

Through our exceptional, collaborative, virtual and physical facilities, we enable the adoption and acceleration of new technologies for advanced modelling and simulation, while improving learning and developing awareness of state-of-the-art. Engaging with organisations large and small, we help to provide access to the right tools, resources, skills and technologies, resulting in increased productivity and faster, more informed decision-making.

As a trusted and neutral provider, our vision is to drive a practical revolution in engineering capability and design, working with organisations to reduce risk in the design phase, product development costs and time to market.

For further information about how CFMS can help your business, call our team today on 0117 906 1100 or email: info@cfms.org.uk.

About the National Composites Centre (NCC)

The NCC Mission is to accelerate the growth of UK industrial output by enabling design and manufacturing enterprises to deliver winning solutions in the application of composites.

In November 2009 the Government launched the UK Composites Strategy*. This highlights the importance of composites to the future of UK manufacturing and the Government’s plans for ensuring that the UK has the means to succeed in intensely competitive global markets.

A key part of this strategy was the establishment of the NCC, which will bring together dynamic companies and enterprising academics to develop new technologies for the design and rapid manufacture of high-quality composite products. The combination of academic and business strengths will speed progress from laboratory to design to factory and into products.

The UK Composites Strategy

Key Objectives:

- Provide manufacturing facilities at an industrial scale and rapid manufacturing processes capable of building prototypes to validate design concepts

- Be the hub of the UK’s effort to develop and implement rapid composite manufacturing technologies and systems.

- Lead the co-ordination of a strengthened network of regional centres of composites excellence

- Provide direction and focus for fundamental research and collaborative links with UK universities

- Help to develop and co-ordinate training to support the skills base necessary for applying advanced and specialist composite technologies